Professional CNC machining - Turning, milling, automatic lathes

Machine park

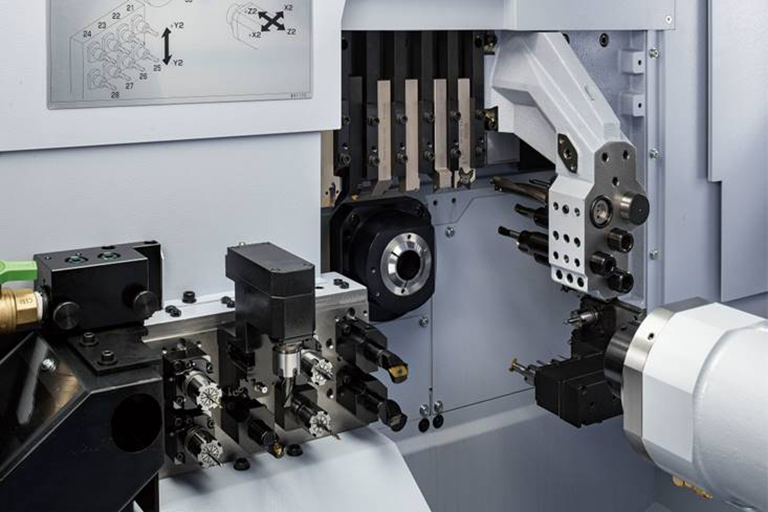

The new generation of design provides high power, maximum rigidity and high-capacity drives suitable for machining large-diameter workpieces.

Key features:

The perfect combination of ergonomics, high productivity and efficiency

Productivity boosted by advanced CNC control

High-speed rapid traverse and powered headstock auxiliary axis significantly reduce machining time

The newly installed movable control panel allows optimum setting at any time

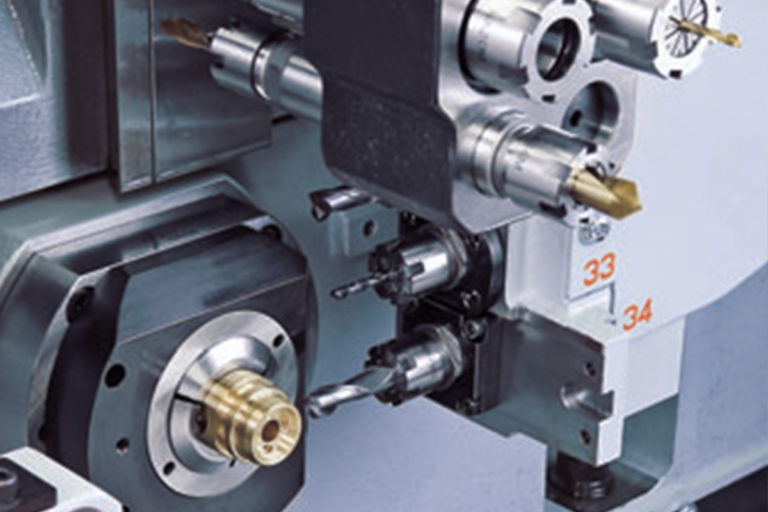

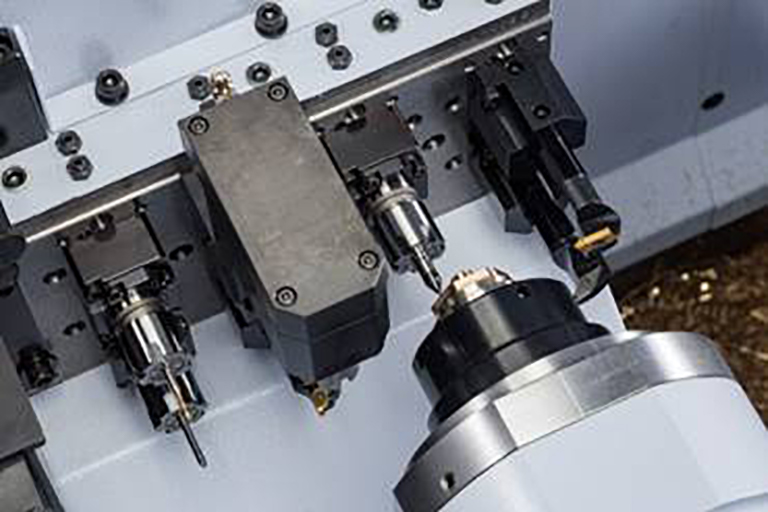

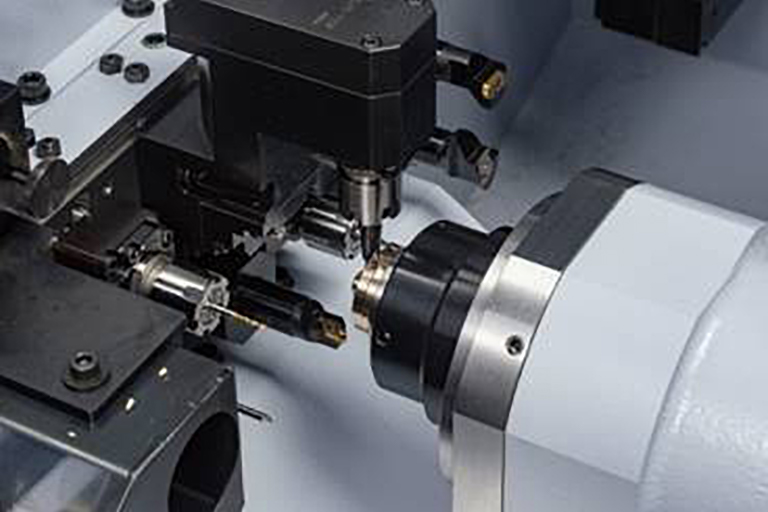

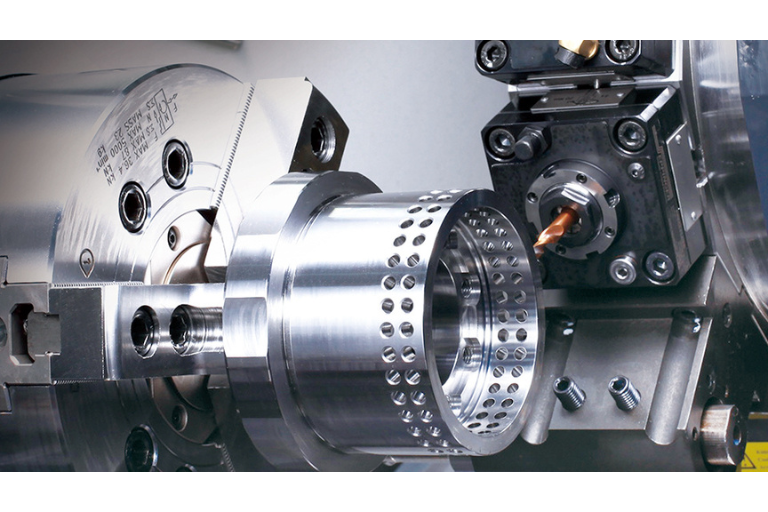

The SR-32J/JN is designed for complex machining of short workpieces with large diameters

The new modular design increases the flexibility of the machine, provides higher rigidity, greater productivity and precision machining.

Key features:

Perfect combination of ergonomics, high accuracy and efficiency

Productivity boosted by advanced CNC control

High-speed rapid traverse and powered headstock auxiliary axis significantly reduce machining time

Movable control panel allows optimum adjustment to suit the operator

Rear operation unit (Type B) with 8 spindles for the installation of driven tools in all positions as standard

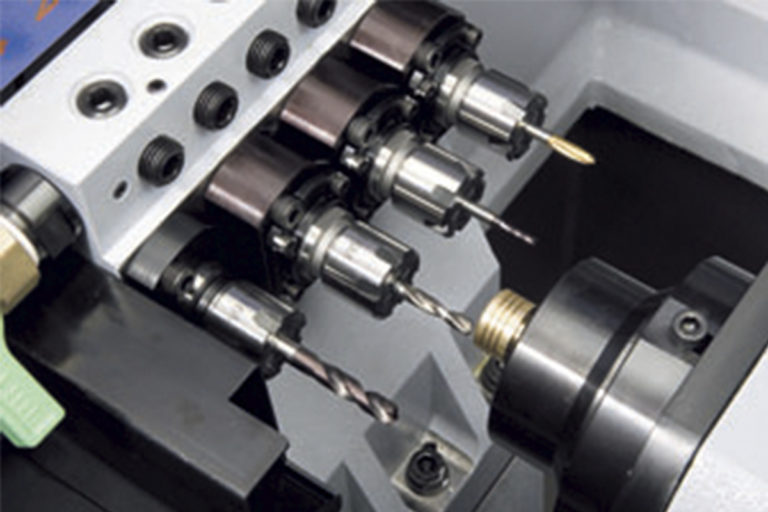

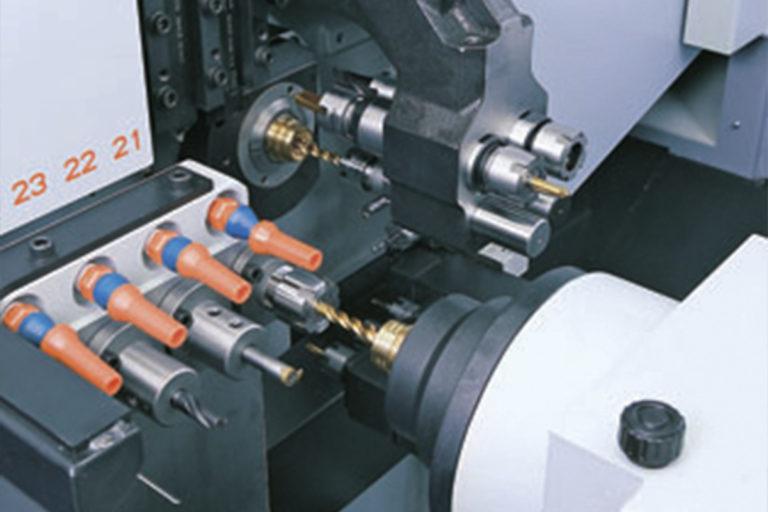

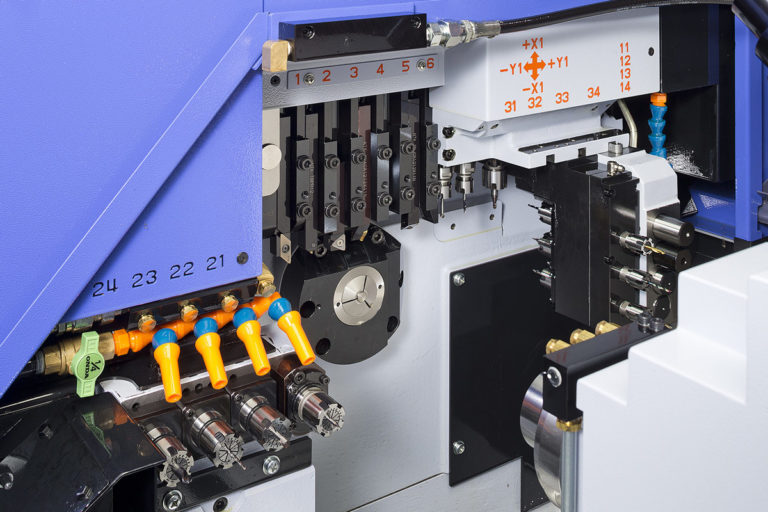

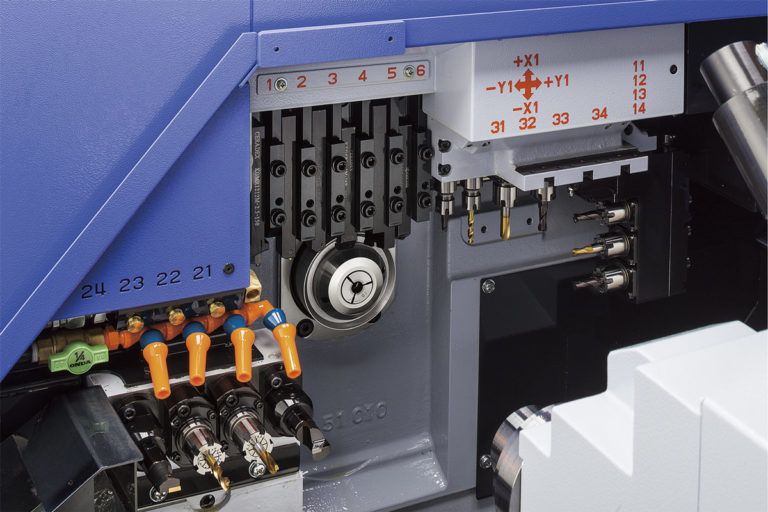

The SB-20R Type G offers a wide range of machining operations thanks to its unique function of switching between guided sleeve and nonguided sleeve modes.

Key features:

Maximum workpiece diameter: 20 mm

Flexible tool systems allow almost unlimited variants for the machining of complex workpieces

Available 4 types of toolholdersso you can choose the configuration best suited to your production requirements.

Maximum variety of tool configurations provides performance to meet the needs of many industries

Flexibility of tool systems includes the possibility to combine the choice of vice and cartridge units

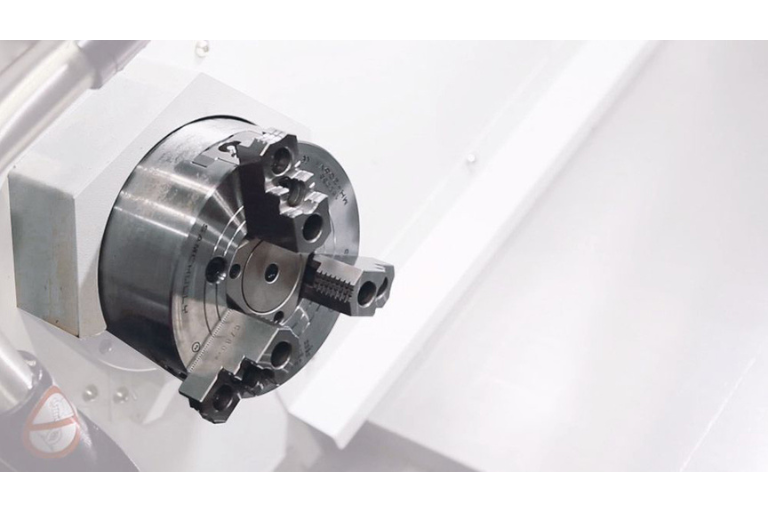

The Lynx 2100/2600 series are modern, compact horizontal lathes that excel in productivity and precision. Designed for the most demanding tasks, they provide reliability and high accuracy in precision production.

Key features:

High precision for heavy machining - robust construction and powerful spindle (up to 6000 rpm) guarantee excellent quality under difficult conditions

Exceptional performance - rigid linear guides on rollers and a reliable turret with space for 12 tools reduce machining times and increase productivity

Flexible options for attaching workpieces - handles in the sizes 152 mm, 203 mm and 254 mm

Large processing range - max. turning diameter 350 mm, max. length 550 mm

Proven reliability - More than 25,000 machines sold worldwide confirm Lynx's position as one of the most trusted turning centres